IRD-3DE

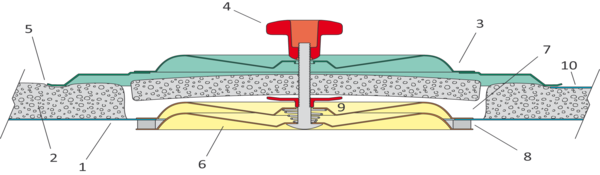

- For rectangular ducts with outside insulation

- Fitted with a 3rd cover plate (3DE)

- Optimal thermal insulation

- Duct wall

- Insulation (minimum and maximum insulation thicknesses: see list below)

- The IRD-3DE access door is made of an RD access door with longer bolts fitted with a cover plate (3DE).

-

The cover plate 3DE should only apply a light pressure on the soft insulating material: the knobs (protected design) must therefore be tightened lightly.

-

The cut edge of the insulation is covered by the cover plate and offers a pleasing appearance.

-

The inside covers guarantee the air-tightness of the access door: the knobs must therefore be fastened firmly.

-

The air pocket trapped between the cover plate and the access door offers good insulating properties.To avoid any convection currents insulation chunks can be stuffed into the hollow spaces between the cover plate and the access door. This is also suggested in order to increase the sound insulating properties of the access door.

-

To maximize the range of possible insulation thicknesses, metal knobs on the inner door (they are less bulky than the plastic ones) are used.

- The IRD-3DE access doors can theoretically also be installed on insulated double-wall rectangular ducts.

Available opening dimensions and insulation thicknesses

21 200 × 100 mm A = min. 10 mm / max. 150 mm

32 300 × 200 mm A = min. 10 mm / max. 150 mm

42 400 × 200 mm A = min. 10 mm / max. 145 mm

43 400 × 300 mm A = min. 10 mm / max. 145 mm

53 500 × 300 mm A = min. 10 mm / max. 145 mm

54 500 × 400 mm A = min. 10 mm / max. 130 mm

64 600 × 400 mm A = min. 10 mm / max. 130 mm

65 600 × 500 mm A = min. 10 mm / max. 130 mm

75 700 × 500 mm A = min. 10 mm / max. 130 mm

![[Translate to English:] METU Symbol - EURO EURO](/fileadmin/_processed_/4/5/csm_web_metu_symbol_euro_f1b5afbfe7.png)