Round Connections

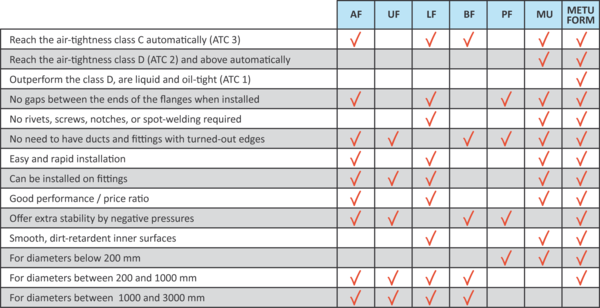

In most cases your first choices would be the MU Overcollars and the AF Circular Flanges, and of course the METU-FORM duct system for your higher requirements regarding tightness and energy performance.

AF Circular Flanges

Most popular flange allowing to connect round ducts together.

Ø 200 to 3000 mm

Air-tightness class C (DIN EN 12237)

Air-tightness class ATC3 (DIN EN 16798-3)

Assembly with SR joininig clips

LF Circular Flanges

To connect ducts and fittings with tured-out edges (Vanstone) together.

Ø 200 to 3000 mm

Air-tightness class C (DIN EN 12237)

Air-tightness class ATC3 (DIN EN 16798-3)

Assembly with SR Joininig Cips

BF Circular Flanges

To connect round ducts together. These flanges enter deeper into the ducts, translating into more flexibility.

Ø 200 to 3000 mm

Air-tightness class C (DIN EN 12237)

Air-tightness class ATC3 (DIN EN 16798-3)

Assembly with SR Joininig Cips

UF Circular Flanges

To connect round ducts together. This UF flange requires more work than the others including the application of a sealant.

For duct-Ø from 200 to 3000 mm

Air-tightness class C (DIN EN 12237), ATC3 (DIN EN 16798-3)

Assembly with SR Joininig Cips

SR Joining Clips

Allow to assemble the AF, UF, LF and BF flanges together.

Must be ordered with gasket in order to achieve the air-tightness class C / ATC3

MU Overcollars / Quick Sleeves

Economical connections for small round duct.

Duct-Ø from 71 to 315 mm

Air-tightness D (DIN EN 12237) or ATC2 (DIN EN 16798-3)

PF Pressed Flanges

For duct diameters from 80 to 180 mm

Air-tightness class C (DIN EN 12237) or ATC 3 (DIN EN 16798-3)

Assembly with SS joining clips

SS Joining Clips

For the assembly of ducts fitted with PF flanges.

Must be ordered with gasket in order to achieve the air-tightness class C / ATC3

METU-FORM Duct System

Laser welded ducts and welded fittings (Ø 80 to 1000 mm)

Formed-on Parallel Flanges. Airtight, oiltight, with smooth inner surfaces and an easy assembly.

MRF Measuring Bands

For the precise measurement of the inner duct diameters according to DIN EN 1506

NZ and PNZ Notching Tools

For the punching of accurate notches (Distance: approx. every 80 mm) for the fastening of AF and BF circular flanges into the ducts or fittings.

Nut Runners SE

For the tightening of SR Joining Clip nuts within seconds.