Testing Procedures

Standard devices allowing to determine the leakages in an air-duct section do not perform well when leakages lie below the air tightness class D (DIN EN 12237) or the class ATC 2 (DIN EN 16798-3).

This is why we used more precise means to determine the leakages of our METU-FORM ducts. This is also necessary, since we also want to test the liquid-tightness and above all the oil-tightness of the system.

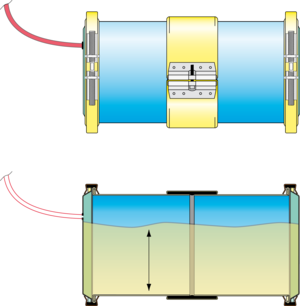

Oil under Pressure

An air-duct section made of METU-FORM components is filled partially with oil. A positive pressure of 4400 Pa is applied during 8 hours. No leakages should appear.

In the meantime our new test standards consist of a positive pressure of 10'000 Pa during an entire week, with pressure changes to make sure the parts resist fluctuations.

The above tests are conducted under ideal circumstances.

Tightness characteristics and the useful life of the system depend for example on:

- the resistance of the gasket to the transported chemicals,

- the operating temperatures including the eventual peaks,

- the presence of contaminants (could be water from condensation, different oils, etc.),

- the effects of corrosion.