Round Flanges AF

Most popular METU circular flange

Fitted with a metallic sealing-lip.

Assembly thanks to SR Joining Clips.

Also available in stainless steel (AF and AF-A)

Manufactured in Germany, Japan and Taiwan.

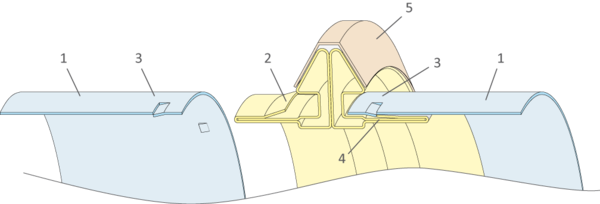

- Duct wall

- Metal sealing lip

- The notches prevent the flange from being pulled out. Drill screws and blind rivets can also be used.

- By hammering the flange into the duct, the tapered sealing lip, whose diameter is larger than the inner diameter of the duct, is forced down. The resulting enormous pressure between the sealing lip and the duct wall makes the connection air-tight.

- When SR Joining Clips with gasket are used, no gasket application on the flange face is necessary. This prevents the gasket from being damaged during installation and speeds up the assembly.

For inner-duct diameters from 200 up to 3000mm. In-between diameters are also available. IMPORTANT: Please indicate if flanges are intended for fittings, in which case their Ø is made 3 mm smaller.

Fastening in the duct through notches (see Notching Tools) and blind-rivets.

Screws are less recommended, as they protrude inside the duct, hindering the air-flow and the cleaning operations, and could be the cause of leakages.

To reach the air-tightness class C no additional measures, such as the use of adhesive tapes, sealants or mastic, are necessary. The necessary SR Joining Clips must be ordered with gasket.

The air-tightness class D or ATC 2 can also be reached when mastic is applied (refer to the instructions). Liquid-tightness see ZI-703.

The flanges stiffen the ducts and help maintaining their round shape. They also improve the resistance of the ducts under negative pressures. Ducts should nevertheless be strong enough by themselves and resist the required pressures (+ or -) without taking the flanges into account.

The flange is automatically centered in the duct. No gap is formed between the two ends of the flange.

Available in galvanized steel. Stainless steel V2A (1.4301 ASTM 304) and V4A (1.4404 ASTM 316) upon request. There are a few technical differences between the flanges in galvanized steel and the ones in stainless steel. Please refer to information on metals (ZI-101) and the page about the AF flange dimensions.

Duct ends must be cut straight.

The flanges can be installed on ducts with stiffening ribs. In these cases, notches cannot be used. It is recommended to flatten the stiffening beads at the ends of the ducts and to fix the flanges with rivets and/or screws. Sealing measures (sealants, mastic) are required to reach the air-tightness class C.

![[Translate to English:] METU Symbol - EURO EURO](/fileadmin/_processed_/4/5/csm_web_metu_symbol_euro_f1b5afbfe7.png)