Notching Tools NZ and PNZ

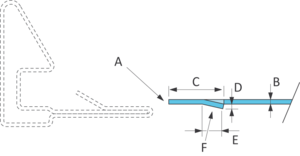

A) End of round duct or fitting

B) Duct wall thickness

C) Distance accoring to the diameter (*)

D) 1 × the duct wall thickness (galv. steel = max. 1,5 mm, stainless steel = max. 1,2 mm)

E) 4 × the duct wall thickness

F) Notches must protrude inside the duct !

(*)

Duct-Ø 200 to 499 mm : 7 mm

Duct-Ø 500 to 999 mm : 9 mm

Duct-Ø 1000 to 3000 mm : 15 mm

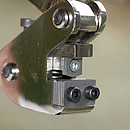

Comfortable and robust hand-operated notching tools with hardened, interchangeable cutters. The body is designed to provide a wide-end stop surface to ensure that the notch is not only at the correct distance, but at the right angle as well.

This robust pneumatic-hydraulic notching tool allows a fatigue-free, comfortable and rapid operation. The cutter head is robust but still leaves the cutting area in clear view.

Please read the owner´s manual carefully!

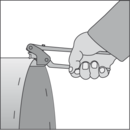

Notches are punched along the entire circumference of the duct or fitting before inserting the circular flanges. The distance between the notches should be between 50 and 100 mm.

Start by making tests using scrap material. The depth of the notch must correspond to the duct wall thickness. Corrections can be made by adjusting the stop screw. Under normal operating conditions the cutters have a long service life. If the upper cutter becomes slightly blunt it may be regrounded a little. By doing so, do not modify the cutter thickness, since this would affect the cutting clearance. The lower cutter can be rotated four times and therefore hardly needs any regrinding. Applying occasionally a few drops of oil in the joints will extend the tool’s life expectancy considerably.

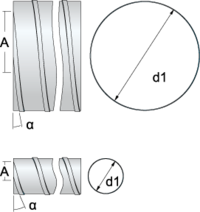

It is not possible to create notches on seams (A), and they have no use when created on a stiffening rib (B). In these areas the flange must additionally be fastened using blind rivets or self-tapping screws.

On larger duct diameters the seam crosses the end of the duct at a much smaller angle. The distance where a notch cannot be created might therefore be longer than the prescribed 100 mm (A). In such cases the flange must be secured with blind rivets or self-tapping screws.

Please refer to the operation manual which is available in our website.

The head of the pneumatic notching tool has been especially designed by METU Meinig AG to create the notches for the METU AF and BF circular flanges. METU Meinig AG is therefore responsible for the proper functioning of this specific part. The main element of the pneumatic notching tool is manufactured by the company Titgemeyer. Should you encounter any problems with this part thank you for contacting Titgemeyer directly.

Titgemeyer GmbH & Co. KG (www.titgemeyer.de)

![[Translate to English:] METU Symbol - EURO EURO](/fileadmin/_processed_/4/5/csm_web_metu_symbol_euro_f1b5afbfe7.png)