PF Instructions

To control the inner duct-Ø please refer to the MRF measuring band instructions.

The circumference / diameters of the PF circular flanges cannot be modified. For this reason, the PF circular flanges cannot always be installed around the ends of fittings. Should you wish to use the PF flanges on fittings, it is recommended that you conduct a few tests with PF samples first.

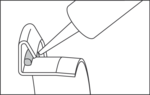

Before inserting the flange into the duct apply an adequate sealant into the groove of the flange along its entire circumference.

We therefore recommend to spot weld or rivet the seam in the vicinity of the duct ends before inserting the flange.

If the seam is too high (A) preventing the flange from being inserted all the way in, grind it down (B).

Screws are less recommended, as they protrude inside the duct, hindering the air-flow and the cleaning operations, and could be the cause of leakages.

PF made of Stainless Steel (V2A)

Cracks can appear on the stainless steel versions. They are unavoidable and consequently no reason for a claim.

For further instructions please refer to the SS Joining Clips section.