LF Instructions

To control the inner duct-Ø please refer to the MRF measuring band instructions. In case of deviations beyond the tolerances, read the values on the scale and send us that information when placing your order.

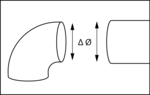

Fittings:

Please advise upon ordering if the flanges are intended for fittings, as they are made smaller (diameter about 3 mm smaller / circumference about 9 mm shorter). The SR joining clip bridges

these small diameter differences.

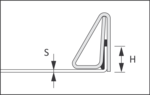

The stability of the LF flange depends on the stability of the duct´s turned-out edge. The turned-out edge should therefore be made as sturdy as possible:

| LF Ø | H Min. | H Max. | S Max. |

| LF 200 to 450 mm | 5 mm | 7 mm | 1,0 mm |

| LF 500 to 900 mm | 7 mm | 12 mm | 1,5 mm |

| LF 1000 to 1600 mm | 10 mm | 15 mm | 1,5 mm |

| CAUTION: LF 1000 in stainless steel = medium profile size |

Modifications, such as a reduction of the turned-out edge height, or the grinding of welds or seams, might be necessary. Information provided without warranties.

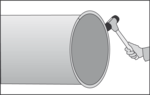

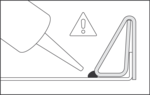

The flange is snapped on the turned-out edge of the duct or fitting. Start with one end of the flange and work around.

Should the flange be slightly blocked with its slot on the turned out edge, use a rubber mallet till the ends of the flange fit tightly together.

Should a gap remain between both flange ends, the duct-Ø is too large. You can either measure the precise duct-Ø by using our MRF Measuring Band and order a corresponding special LF Circular Flange, or fill the gap with mastic.

Should the LF Circular Flange be too large, you can either shorten the flange or order a special LF Circular Flange after having precisely measured the duct-Ø.

For large diameters the ends of the LF Circular Flange should be connected with a welding point to keep the flange from coming off the duct during transport.

Stainless steel LF's versions are delivered without sealing compound in the tapered slot.There may also be residues of protective film in the flange (to be considered by higher temperatures). The flange must be sealed

all around its circumference.

For further instructions please refer to the SR Joining Clips section.