Profile Frame Stability

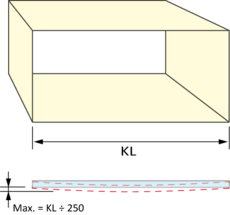

The profile´s load-bearing capacity and stability against deflection depend on the operating pressures and the width of the duct. The recommended dimensions are maximum duct widths (KL = Largest edge length of the duct´s cross-section).

International norms indicate that a flange profile under operating pressure should not deflect more than the 250th part of the total duct width (the allowed deflection of a 1000 mm wide duct would be for instance 4 mm). The figures provided on the table below take this requirement into account.

Prerequisites are sufficiently stiffened duct-walls with an adequate sheet metal thickness and the recommended use of clamps (please refer to the “Clamping Recommendations“).

The operating range of the rectangular flanges can be increased through the installation of tie rods near the flanges. The reference “with tie rod” means that a tie rod must be installed close to the flange (the distance from the flange must not exceed 50 mm).

| Max. Pressure Pa (+/-) | M2-0,7 | M2-0,9 | M3-0,9 | M3-1,2 | M4-1,2 | M4-1,5 |

|---|---|---|---|---|---|---|

| 500 Pa w/o Tie Rods | 1000 | 1200 | 1600 | 2000 | 2500 | 3000 |

| 500 Pa with Tie Rods | - | 1400 | 2500 | 3500 | 4000 | 5000 |

| 1000 Pa w/o Tie Rods | 800 | 1000 | 1400 | 1600 | 2000 | 2500 |

| 1000 Pa with Tie Rods | - | 1200 | 1800 | 2500 | 3500 | 4000 |

| 1500 Pa w/o Tie Rods | 700 | 900 | 1300 | 1500 | 1800 | 2200 |

| 1500 Pa with Tie Rods | - | 1200 | 1800 | 2400 | 3200 | 3600 |

| 2000 Pa w/o Tie Rods | 600 | 800 | 1200 | 1400 | 1600 | 1800 |

| 2000 Pa with Tie Rods | - | 1200 | 1700 | 2200 | 2800 | 3400 |

| 2500 Pa w/o Tie Rods | 600 | 800 | 1000 | 1200 | 1400 | 1600 |

| 2500 Pa with Tie Rods | - | 1200 | 1600 | 2000 | 2500 | 3000 |

| 3000 Pa w/o Tie Rods | 600 | 700 | 900 | 1100 | 1300 | 1500 |

| 3000 Pa with Tie Rods | - | 1100 | 1500 | 1900 | 2400 | 2800 |

| 3500 Pa w/o Tie Rods | - | 600 | 800 | 1000 | 1200 | 1400 |

| 3500 Pa with Tie Rods | - | 1000 | 1400 | 1800 | 2200 | 2600 |

| 4000 Pa w/o Tie Rods | - | 500 | 600 | 800 | 1000 | 1200 |

| 4000 Pa with Tie Rods | - | 1000 | 1200 | 1600 | 2000 | 2400 |

Caution

The above recommendations are based on tests which have been conducted on test duct work according to the norms.

Other duct constructions, insufficiently stiffened duct walls, different sheet metal thickness, bad quality lock seams, and so on, may have negative effects on the stability of the air duct.

The execution of the duct construction according to the above recommendations constitutes therefore no guarantee for sufficient duct stability and does not take away the responsibility from the duct work manufacturer to conduct his own tests. Special conditions such as pulsating air, sudden pressure changes, vibrations, man loads, damaged duct, etc. have not been taken into consideration. In such cases the ductwork should be manufactured and tested according to these requirements.