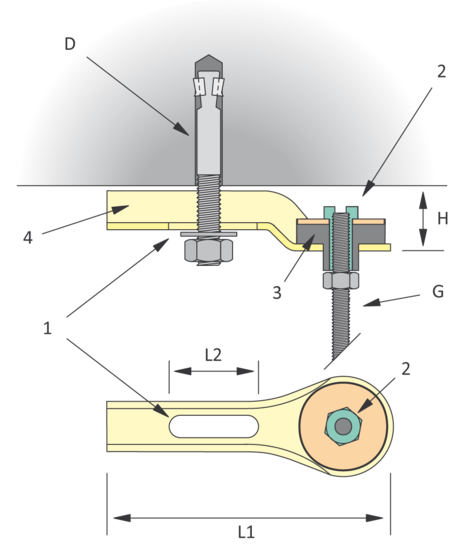

Ceiling Brackets DB

Useful, when the exact position of the threaded rod is difficult to determine.

The sturdy bracket can be moved along the oval hole and rotated.

It allows the vertical alignment of the threaded rod.

That way the plug hole does not have to be drilled with great accuracy.

The integrated rubber GP provides acoustic isolation.

- The slot allows a lateral adjustment of up to 40 mm.

- Threaded sleeve. The thread does not go all the way through and acts that way as a stop.

- The GP Rubber Isolator (≈ 55° Shore) with moulded-on washer provides acoustic insulation.

- The rigid bracket is made of heavy gage press-formed galvanized steel.

| Art.Nr. | Ceiling Brackets | Max.N | L1 | L2 | H | G | D max. | GP |

| F01V-1001 | DB M6 galv | 300 | 140 | 40 | 22 | M6 | M10 | M10 |

| F01V-1002 | DB M8 galv | 300 | 140 | 40 | 22 | M8 | M10 | M10 |

| F01V-1003 | DB M10 galv | 600 | 160 | 40 | 32 | M10 | M12 | M12 |

Load Bearing Capacity

The indicated maximum load-bearing capacity is in accordance with the European Norm EN 12236 and can therefore be used integrally. The breaking load is three times higher.

Fix the plug at a distance of 30-90 mm from duct. The greatest stability is achieved by ensuring that the distance between the plug and the threaded rod is reduced to a minimum.

Assemble the Bracket, the Rubber Isolator and the sleeve with thread. Feed the threaded rod through the sleeve and tighten the nut.

The nut on the plug is then tightened, ensuring that the drop rod is exactly vertical.

![[Translate to English:] METU Symbol - EURO EURO](/fileadmin/_processed_/4/5/csm_web_metu_symbol_euro_f1b5afbfe7.png)