ZI-207 SW Gasket

SW Mineral Wool Gasket

Material

The SW mineral wool is a self-adhesive, asbestos-free, high-temperature gasket. Thanks to their stability by high temperatures and their low caloric conductibility, the mineral fibers are a very good insulating material.

Self-adhesive, asbestos-free, high temperature mineral wool gasket (Rock wool).

Fiber-Ø: 5 to 6 μ, and 1,5 to 2,5 μ. Color: white.

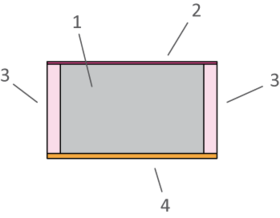

Without halogen or polytetrafluorethylene. Contains some silicone (Fig. 01, Point 3).

Adhesive: Polyzol PSA SE-6101. Protective foil: PE film with silicone (*) layer.

(*) All self-adhesive products are usually fitted with a siliconized protective foil applied over the bounding surface. To install the product this foil must be removed: it is therefore not part of the product. The gasket material itself is silicon-free. It is possible however, that silicon traces are detected, as they can be transmitted to other parts during handling. An absolute silicon-free guarantee can, for that reason, not be given.

PWIS: please refer to the ZI-102

REACH: No information available from our supplier. See also the REACH information.

Operating Temperatures

From –50°C to +200°C.

It is recommended to eventually replace the SW rock wool gasket on METU-SYSTEM

products which have been subjected to operating temperatures above +200°C, as the gasket might crumble away.

Behavior in Fire

Building Material Classification: no information

Fire resistance: no information

Smoke: no information

Food Industry

Not suitable.

Outdoor Exposure

Weather and UV Resistances (DIN 53 386): The fibers are UV resistant.

Ozone resistance (DIN 53 509): Not tested

Resistances

Mineral Oils and Fats: Not resistant

Organic Oils and Fats: Not resistant

Solvents: Not resistant

Caution

The resistances are valid for the fibers only, and not for the adhesives or other components. The adhesives has only a limited resistance against chemically.

Oil Resistance

The fibers themselves are oil-resistant. The gasket will however absorb the oil, negatively influencing the adhesive properties of the bonding agent. The temperature resistances could also be affected.

General Information about Resistances to Chemicals

Chemicals and oils are available in very different qualities. Their properties vary depending on their concentration, operating temperatures, possible mix with other chemicals and the eventual presence of impurities. This is why gasket manufacturers only provide general information about the resistance of their products to various chemicals. In view of the above it is advisable that the client runs some tests in order to assess if the gaskets are suitable for the intended application. We regret not being able to provide more precise information.

REACH

Does not contain any substances (SVHC) which could be of concern according to the REACH extended list dated 13-01-2010.

VDI 6022

Not conform.

Safety Data Sheet

No Information available

Important Information

The present additional information have been compiled carefully. They are only indications intended to provide counsel. They are the result of internal tests and information provided by our suppliers. There is no guarantee for completeness and accuracy. More precise information can only be made available through focused tests on a case by case basis. The provided indications do not discharge the user from conducting his own tests. Please make sure that the product is suitable for the intended use. Changes, errors and omissions excepted. Free translation: the German version prevails.